Industrial Mixers: Batch & Continuous Mixers Explained

Without industrial mixers, numerous industries would not have sufficient product to meet demand. The availability of both batch and continuous mixers...

2 min read

Mixer Direct Sep 1, 2016 12:00:00 AM

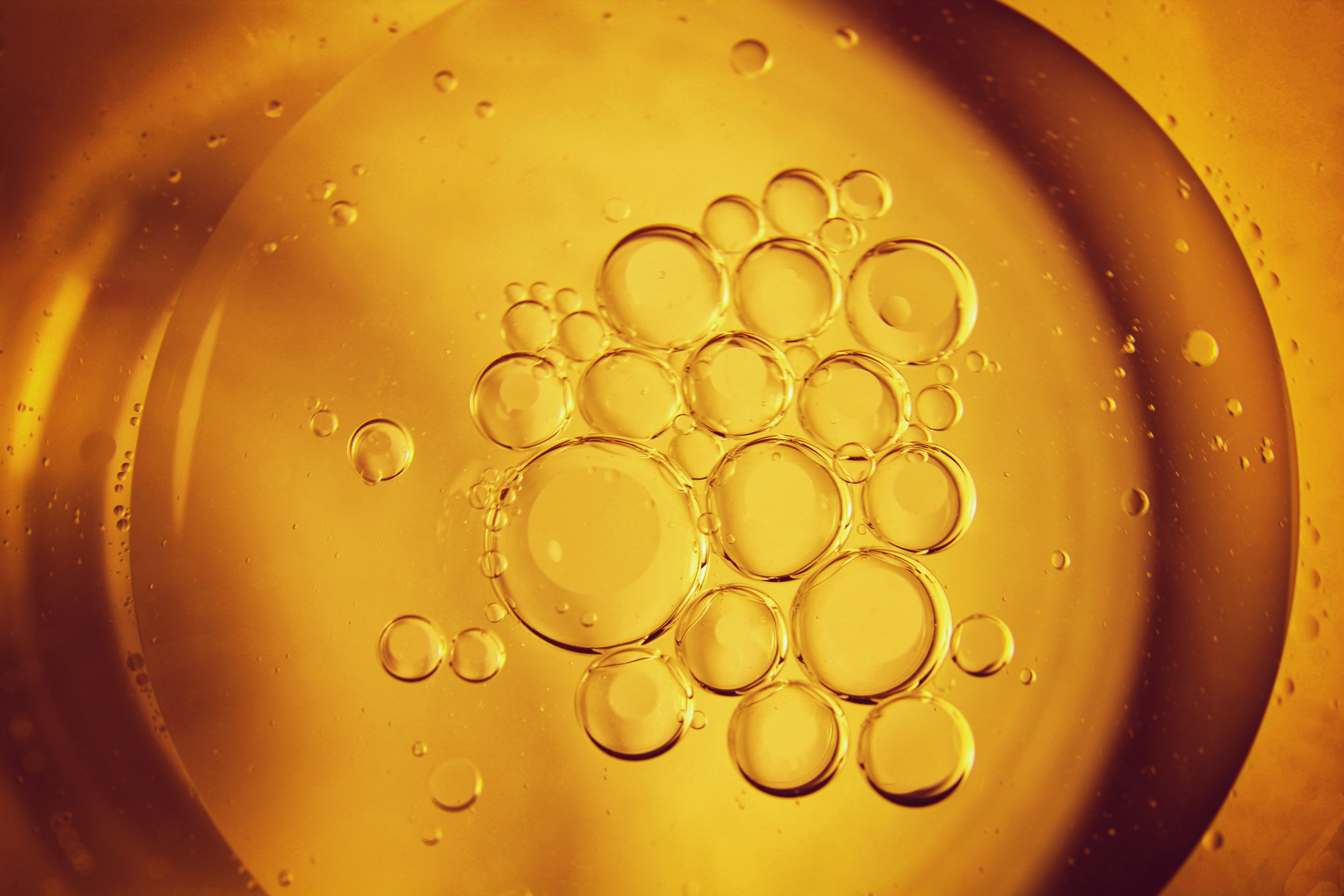

The Mixer Direct DP Line of High Shear Dispersers are utilized across a wide spectrum of process industries. The DP Line is designed for quickly and efficiently imparting powders into liquid while breaking-down agglomerations. DP units also excel in liquid to liquid mixing such as emulsification. This cost effective and versatile line of high shear dispersers is tailored for applications with a viscosity less than 50,000 cps that require aggressive shear and reduced cycle times.

Customize your DP unit by selecting from a variety of motor package options including TEFC motors, air motors, and explosion proof motors. The necessary motor horsepower can be easily calculated based upon 1HP for every 10 gallons of product. Other customization options include: explosion proof controls, safety switches, lifts, digital speed controllers with RPM readout, and more.

.jpg?width=600&name=2017%20Disperser%20System-4(1).jpg)

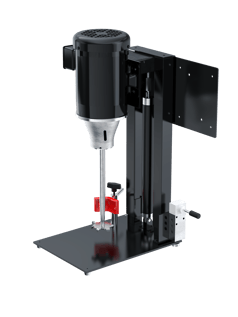

Mixer Direct’s DP1 line is one of the most cost-effective and full featured disperser lines on the market. The DP1 is a single shaft disperser that is designed for low to medium viscosity mixing applications. This unit is typically equipped with a single high shear dispersion blade, but can utilize most Mixer Direct impeller lines as well. For applications requiring increased homogenization, emulsification, and particle reduction, the Mixer Direct DP1 can also be fitted with a rotor stator.

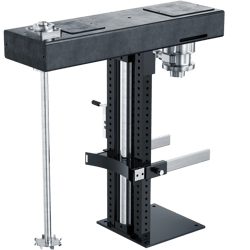

Mixer Direct’s DP2 line stands to fill the mixing industry gap between bench scale dispersers and large floor mount dispersers. This belt-driven unit is designed specifically to be the optimal size and price for applications within the 5-20 gallon range. The DP2 touts a wide variety of mixing blades for high viscosity materials. This unit also allows easy access to allow mixing blades to be easily changed out in less than 30 seconds. This is especially convenient for industries that desire to use the same unit for multiple applications, diverse chemistries, and varying viscosities.

Mixer Direct’s DP2 line stands to fill the mixing industry gap between bench scale dispersers and large floor mount dispersers. This belt-driven unit is designed specifically to be the optimal size and price for applications within the 5-20 gallon range. The DP2 touts a wide variety of mixing blades for high viscosity materials. This unit also allows easy access to allow mixing blades to be easily changed out in less than 30 seconds. This is especially convenient for industries that desire to use the same unit for multiple applications, diverse chemistries, and varying viscosities.

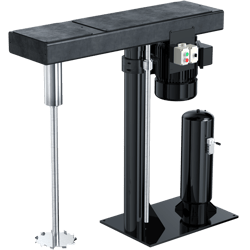

Mixer Direct’s DP3 line is purposefully designed to be of the greatest value for high shear disperser applications ranging from 30-100 gallons. DP3 units are equipped with an air lift that allows the dispersion blade to be placed at any position within the mixing container. This feature is included for dispersing products at a variety of viscosities and to allow easy access for mixing blades to be changed out.

Mixer Direct’s DP4 line is designed for high shear disperser applications ranging volumes of 100-300 gallons. DP4 units are equipped with an air over oil lift that allows the dispersion blade to be placed at any position within the mixing container for multiple applications, diverse chemistries, varying viscosities, and easy access for mixing blades to be quickly changed out. The DP4 unit also conveniently swivels 270 degrees and locks into place after reaching the desired rotation.

Mixer Direct’s DP5 & 6 line is designed for applications ranging volumes of 400-2000 gallons. Both units are equipped with a lift that allows the dispersion blade to be placed at any position within the mixing container for dispersing multiple applications, diverse chemistries, varying viscosities, and easy access for mixing blades to be quickly changed out. Both units also conveniently swivel 270 degrees and lock into place after reaching the desired rotation.

The major industries that utilize Mixer Direct's line of high shear dispersers include adhesives, chemicals, inks, coatings, and paints.

Without industrial mixers, numerous industries would not have sufficient product to meet demand. The availability of both batch and continuous mixers...

Once you have your impeller, motor, and shaft you’ll need to mount the mixer to the container or set up a stand where you can lower the mixer in and...

Imagine two cars, both the same make and model, driving down the highway. One car is well-maintained, with regular oil changes, tune-ups, and tire...