Building a Mixing System: Tank to Impeller Ratios

If you are building a mixing system, one of the first things to consider is the size of the tank compared to the size of the impeller. We look at the...

Before we talk about impellers, we have to get some of the nomenclature straightened out. There are impellers, propellers, blades, foils, and a host of other names for the item that is actually spinning in the mixture. However, most people simply use the word "impeller" as a universal way of saying "that little piece on the end of the shaft that spins around." With that being understood let's look at the different kinds of "impellers" and their flow patterns because, for the most part, flow pattern is determined by the blade.

Propellers are a low shear, high flow mixing impeller. They provide axial flow throughout a vessel, and are excellent options for gentle agitation and solid suspension in low viscosity fluid. Most mixing propellers are available in left hand flow, right hand flow, and steep pitched blades, which provide increased flow rates with slightly more power draw on the motor.

High efficiency impellers (HEIs) are a newer technology compared to the propeller design, which has been around for centuries. HEIs offer low shear and high flow, but at a reduced energy draw. HEIs provide the greatest pumping volume per horsepower of all impeller types. They are most effectively used in low viscosity processes, and can be designed in larger diameters than propellers.

Radial and axial flow turbines are medium shear impellers that impart low to medium flow depending on liquid viscosity. Axial flow turbines allow a mixer to the break up agglomerations and impart solids effectively. Each blade on an axial turbine is pitched at a 45 degree angle and manufactured to leave an edge for the liquid to move over creating a localized shear area. Axial flow turbines will draw more power per volume than the propellers or HEIs as motor power is converted to shear energy. Radial flow turbines creates a radial flow pattern moving away from the impeller towards the vessel's sides. The flow impacts the side and moves in either an upward or downward direction to fill the areas at the impeller's top and bottom and be ejected once more. Some applications benefit greatly from this type of action, namely gas dispersion. Radial flow turbines have a high horsepower draw relative to axial flow turbines and other axial flow impellers.

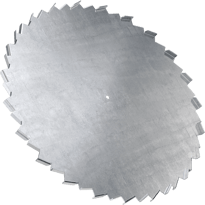

Dispersion blades, or Cowles blades, are high shear, low flow impellers that offer particle reduction, and effectively disperse ingredients to create thorough dispersions and emulsions. A dispersion mixing blade excels at converting the greatest proportion of energy from the motor to shear force. This conversion increases the yield of material to time-consumed ratio. Dispersion blades are available in various styles, catering to the needs of specific product viscosities and process requirements. For increased flow through the mixing vessel, high flow dispersion blades have small sections cut and angled upward or downward around the blade to give more force to the fluid flowing through it. Dispersion blades can have an increased number of teeth around the circumference, and those teeth can be further serrated to increase shearing capacity and particle reduction.

Dispersion blades, or Cowles blades, are high shear, low flow impellers that offer particle reduction, and effectively disperse ingredients to create thorough dispersions and emulsions. A dispersion mixing blade excels at converting the greatest proportion of energy from the motor to shear force. This conversion increases the yield of material to time-consumed ratio. Dispersion blades are available in various styles, catering to the needs of specific product viscosities and process requirements. For increased flow through the mixing vessel, high flow dispersion blades have small sections cut and angled upward or downward around the blade to give more force to the fluid flowing through it. Dispersion blades can have an increased number of teeth around the circumference, and those teeth can be further serrated to increase shearing capacity and particle reduction.

Rotor stators offer the highest shear and lowest flow or pumping capacity. Rotor stators are designed to generate the necessary force to break down solids, create emulsifications and suspensions, and homogenize a mixture with reduced mixing time and high energy output. Rotor stators are available in a variety of configurations to account for changes in particle sizing and process demands. Rotor stators can be installed in in-line mixers or be post mounted for mixing in open vessels.

Choosing a correctly sized impeller, accounting for flow pattern requirements, and impeller material construction are critical to achieving your desired mix and getting the most from your mixer.

To learn more about sizing your impeller, read our article on determining your tank to impeller ratios.

If you are building a mixing system, one of the first things to consider is the size of the tank compared to the size of the impeller. We look at the...

Imagine two cars, both the same make and model, driving down the highway. One car is well-maintained, with regular oil changes, tune-ups, and tire...

If you have no idea what kind of mixer you need, but you know you need one, you are in the right spot.