Adding Portable Mixers to Your Processing Equipment

Portable mixers are a staple for liquid mixing and suspending solids in a host of different industries around the world. These workhorses can be...

Radiation curable coatings are formed by combining different elements of UV light and electron beam energy source. The difference in this type of coating lies in the way the coatings are cured. Types of radiation curable coatings include: additives, photoinitiators, and resins. This form of coating can be used across a broad range of applications.

In creating a radiation curable coating, low energy electrons are used to form a coating. Light is used to solidify the coating formulations, making it useful as a finished product. The use of photoinitiators can react with the light source in order to create the curing process. Light is used in lieu of heat to complete the curing process.

Multiple polymer layers are used to form the coating. Each layer is cured by ultraviolet light or electron beams. This method differs from other methods in that the curing process is accelerated. Once completed, composite materials are combined with silica nanoparticles.

Ultraviolet curing uses medium-pressure mercury vapor lighting as the light source for creating the curing process. Gas-filled lamps can also be used during this process. Radiating intensities range from 200 to 400 nanometers. The UV lamps are used for worker safety during the production phases. These lamps are uniquely designed to focus the intensity on the curing coating.

The coating can also be formed using electron beam curing, which can either be point cathode electron beams or linear cathode electron beams. This method uses electrons to cure the coating surface. An electron beam focuses the electrons from a cathode surface using vacuuming technology. The equipment also features safety features to shield workers from the radiation process.

There are quite a few benefits to using radiation-curable coatings. One benefit is that the finished results are highly resistant to scratches and abrasions as well as chemicals. The process makes it more efficient to manufacture. The coatings can be used in wooden, electronic, plastic, and paper applications. The green process also requires reduced energy consumption. When in use, radiation cure technology is used, there is less waste produced. The process is also conducive to mass production environments due to its efficient curing process and minimum wait time when transition from one process to another process.

• Superior coatings, highly resistant to solvents

• Abrasion and scratch resistant

• Solvent-free technologies used to create products

• Curing process completed within a matter of seconds

• Less heat is produced during the curing process

• Modular design facilitates handling

• Process time reduced, once coating process complete, the next process can begin

• Complex geometries supported

• Curing can be completed in lower temperatures

The process is slightly more than other manufacturing processes. For this reason, the coatings should be used only in cases where there are multiple significant advantages over using another form of coating. Productivity gains are another good application for using this form of coating. Where energy efficient and greener processes are an aspiration, this curing process is widely used.

Infrastructure projects drive much of the demand where wood products are produced. The use of these curing systems are widely used in scenarios like finishing flooring surfaces made from wood or concrete. These coatings can be used in producing three-dimensional parts produced using photosensitive resins. Whenever electronics are produced through printing, these UV curable coatings will likely be broadly used in the future. As the demand for increased use of bio-based material grows, the radiation cure products will grow in popularity. Areas like Asia-Pacific regions are considered among the fastest growing population of consumers of radiation-cured products. An increase in consumer spending has driven the demand for this type of products in Asia.

Radiation curable coatings are created with light instead of heat. The other methods used to form coatings can include a combination of thermal, evaporative, or oxidative methodologies. The process requires other elements to complete the coating process. Photoinitiators aren’t a requirement in other coating applications.

UV radiation coatings can be used across a range of applications. The coatings are used in a range of applications ranging from wood to plastic applications. The efficient coating process enables efficient mass production in industrial environments. Coatings resistant to scratching and abrasions make them use for products that require a higher degree of durability.

Portable mixers are a staple for liquid mixing and suspending solids in a host of different industries around the world. These workhorses can be...

How Is Asphalt Made? Asphalt is just about everywhere. It is used to build roads, parking lots, airport runways, sidewalks, tennis courts,...

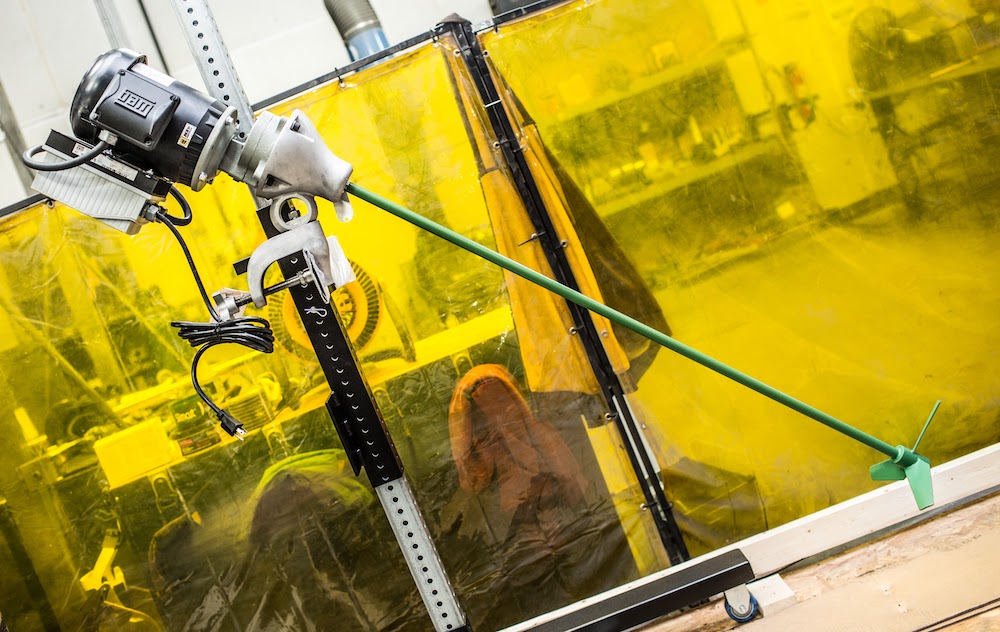

A mixer shaft is simply the piece of material that connects the motor to the impeller. The shaft can vary by diameter, length, and material. The...